Biomass and Coal

Experimental and computational studies on MILD coal combustor / gasifier

Despite the push for renewable energy sources, coal combustion is to play a major role in the energy sector of the world and India in particular. Any increase in the efficiency of the existing coal combustion technologies would lead to a significant reduction in fuel consumption and carbon-dioxide emissions. Motivated by the MILD combustion technique using jets with large velocity differential, efforts are on to combust/gasify high ash Indian coal in an efficient manner. Computational studies which are backed by a single particle coal combustion model, shed light on the combustor dynamics. Insights from the preliminary experiments and computations are used to tailor the composition of the syngas obtained from gasification of coal using mixtures of O2/CO2/H2O.

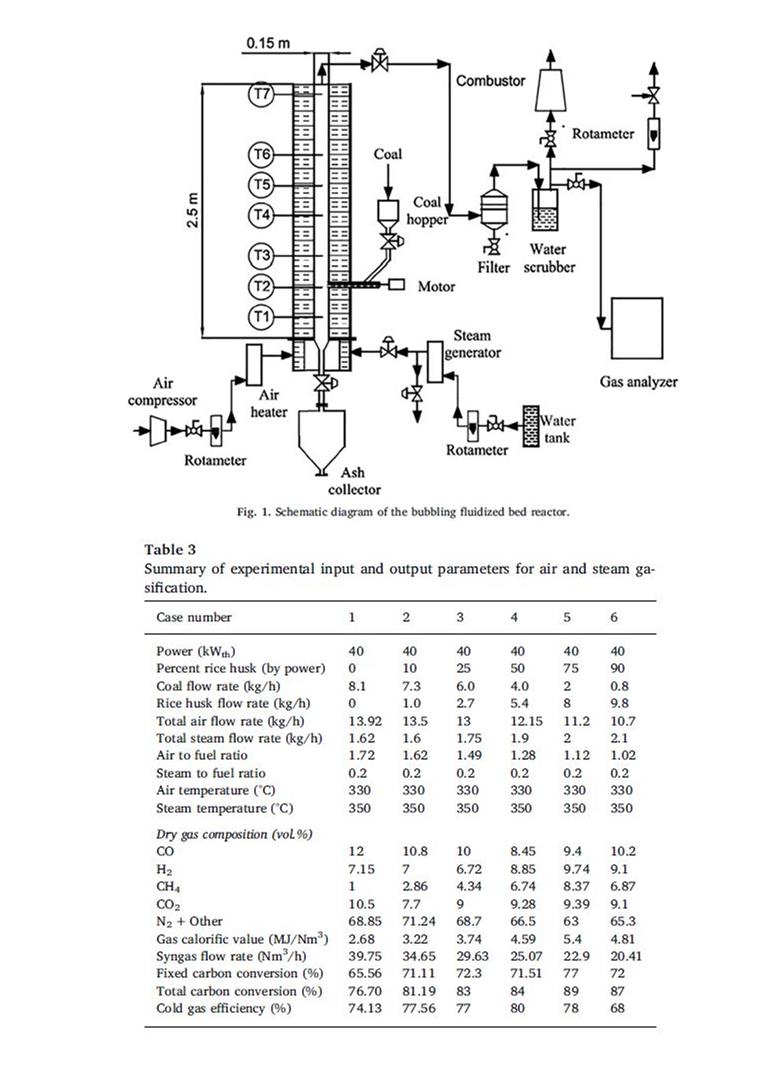

Co-gasification of Indian rice husk and Indian coal with high-ash in bubbling fluidized bed gasification reactor

In this study, co-gasification of rice husk and coal in a lab-scale bubbling bed gasification reactor is reported. Blends of Indian coal with 36% ash and Indian rice husk with 22% ash are used considering proper particle sizes, air flow rates and steam flow rates. Air and steam are used as gasification agents. The reactor is operated at 40 kW (thermal), under atmospheric pressure. Blends are prepared on the basis of power share; rice husk percentage in the blend is varied to contribute to 0–90% of the total power. Results shows that when rice husk is added, all the performance metrics such as total carbon conversion, cold gas efficiency and calorific value of the synthetic gas, show increasing trend. When rice husk contributes from 50% to 75% of the total power, the total carbon conversion is around 89%, cold gas efficiency is around 78% and the calorific value of the synthetic gas is around 5.4 MJ/cubic-meter. Methane yield increases from a volumetric percentage of 1% with 0% rice husk to around 8.37% with 75% rice husk. In summary, a good performance is achieved and blending of rice husk and high ash coal is highly beneficial. (Read More...)

M. Bharath et. al, Applied Thermal Engineering, 137, 2018, (608-615)

Packed bed gasification of biomass with O2/CO2/Steam

Syngas generation using air as a gasifying medium with biomass/coal as fuel is a well established technique used currently in small and medium power and heating applications. It is also possible to tailor the syngas compostion in a single step process by replacing the inert nitrogen component in air with reactive components like CO2 and steam. The resulting syngas, rich in CO and hydrogen can be used in catalytic polymerization reactors (say FT for instance) to produce liquid fuels and fine chemicals. Objective of the work is explore the fundamental characteristics gasification/combustion of biomass in a canonical counter current reactor with mixtures of O2/CO2/steam as oxidizers. Syngas quality improvement, understanding the dynamics of packed beds and framing a theoretical model to predict the propagation rate and gas compostion are the main outcomes of the work.