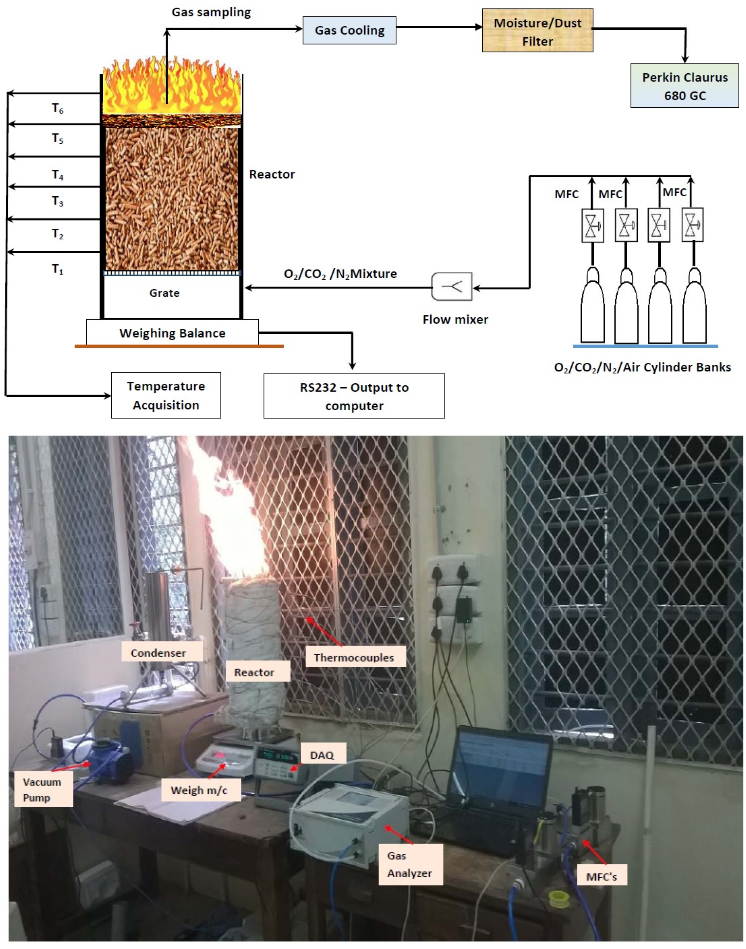

Counter-current biomass packed bed reactor

Understanding the dynamics of gasification in a canonical configuration is essential for reactor design and the counter-current flame propagation mode in a packed bed offers one such with the following advantages - (1) fuel flux, as a function of superficial velocity exhibits universal characteristics with distinct regimes (gasification and combustion), (2) tar fraction in product gases under counter-current configuration is much less compared to co-current (updraft) systems and hence a preferred configuration for downdraft gasifiers, small (cooking) and medium scale (industrial heating) systems, (3) flame propagation in these practical configurations is analogous to packed bed systems with a coordinate frame fixed to the unburnt fuel, and (4) single particle models developed using packed bed systems can be extended to fluidized bed configurations as well. A 108 mm dia, 500 mm long counter-current packed reactor is operational in our lab; it is instrumented to measure flame propagation rate, fuel consumption rate and exit gas composition (using both NDIR based gas analyzer and a GC). The reactor is currently being used to measure the 'net-CO2 and steam' conversion potential of biomass.

Lab-scale counter-current biomass packed bed reactor

Faculty incharge:

Dr. S. Varunkumar